POWER UP WITH THE BEST

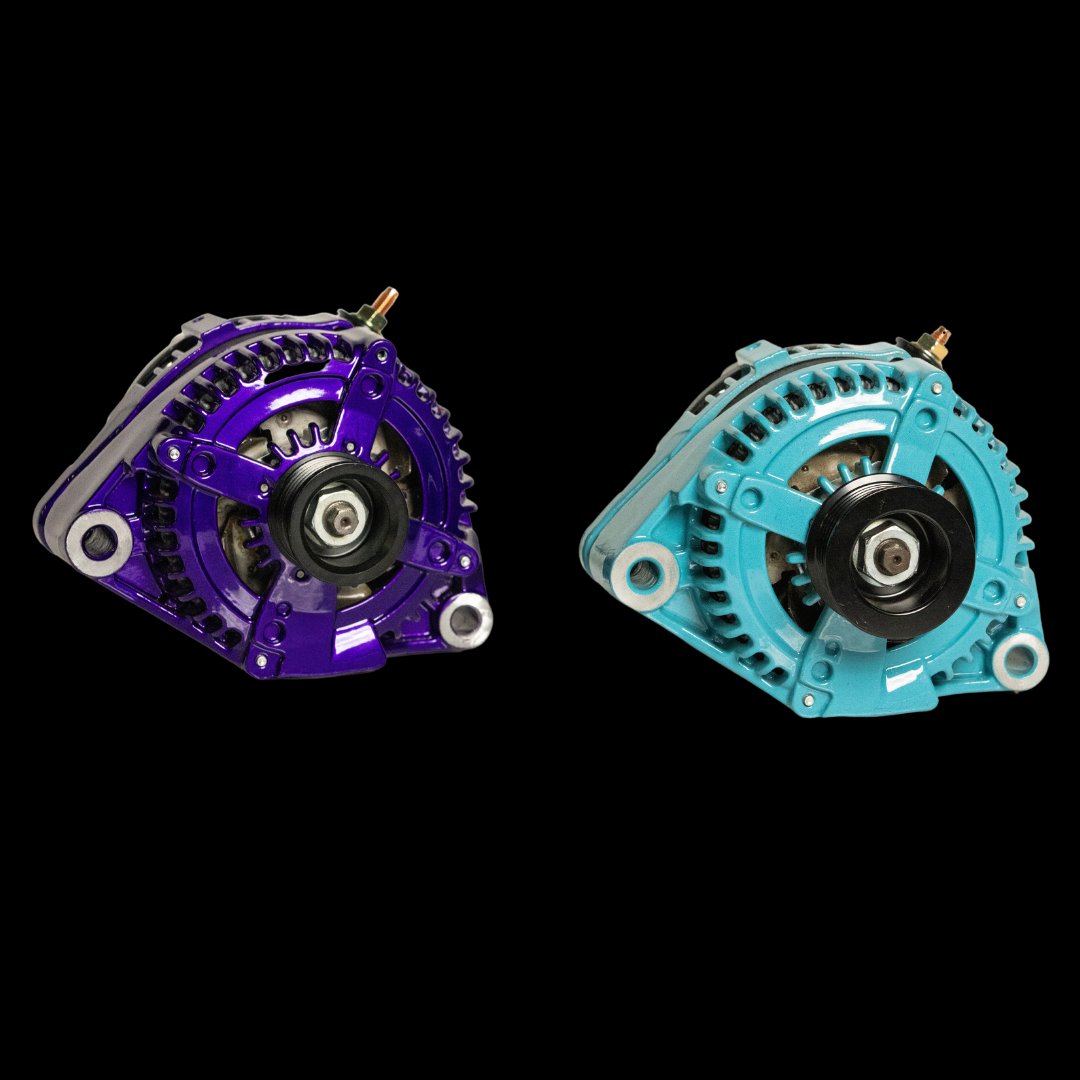

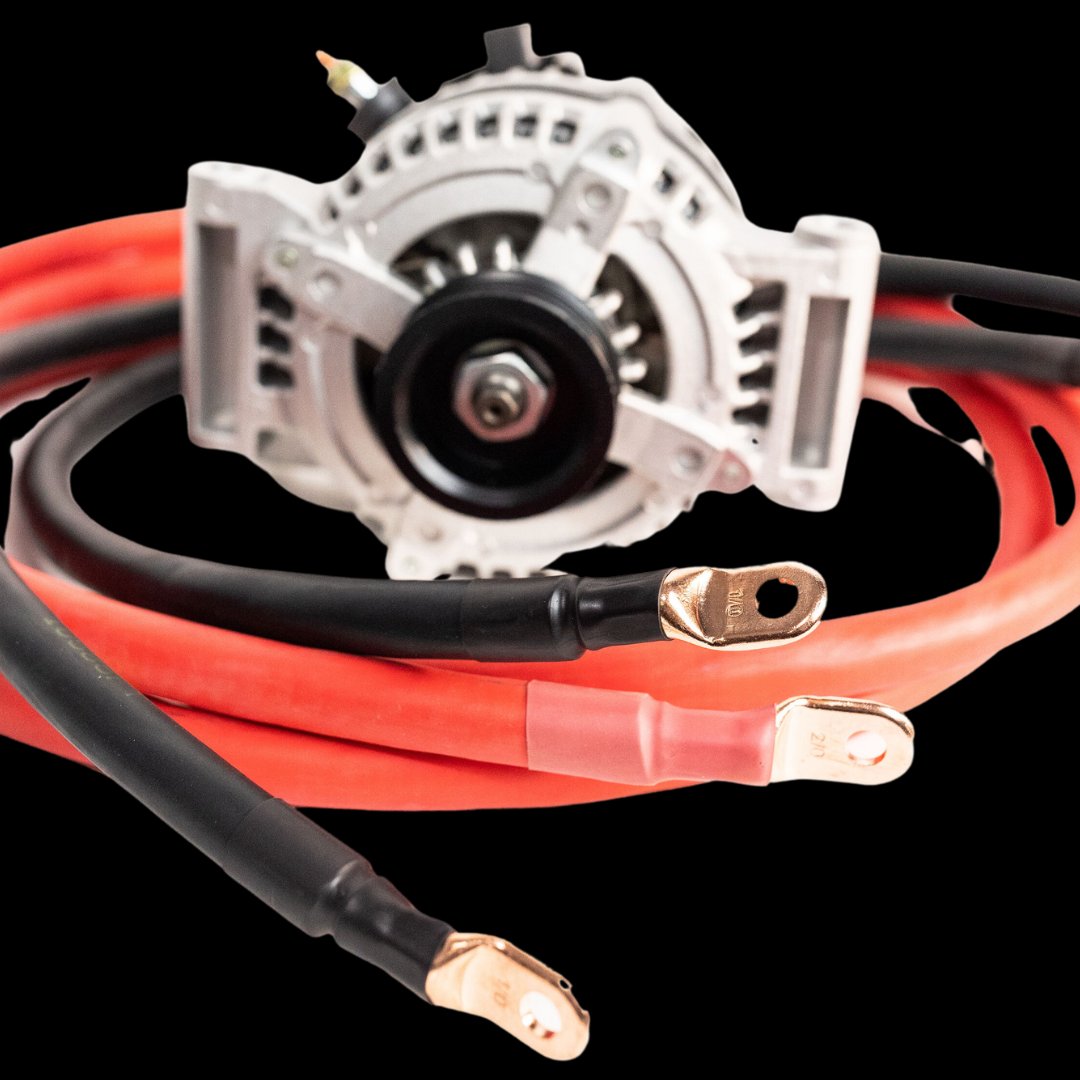

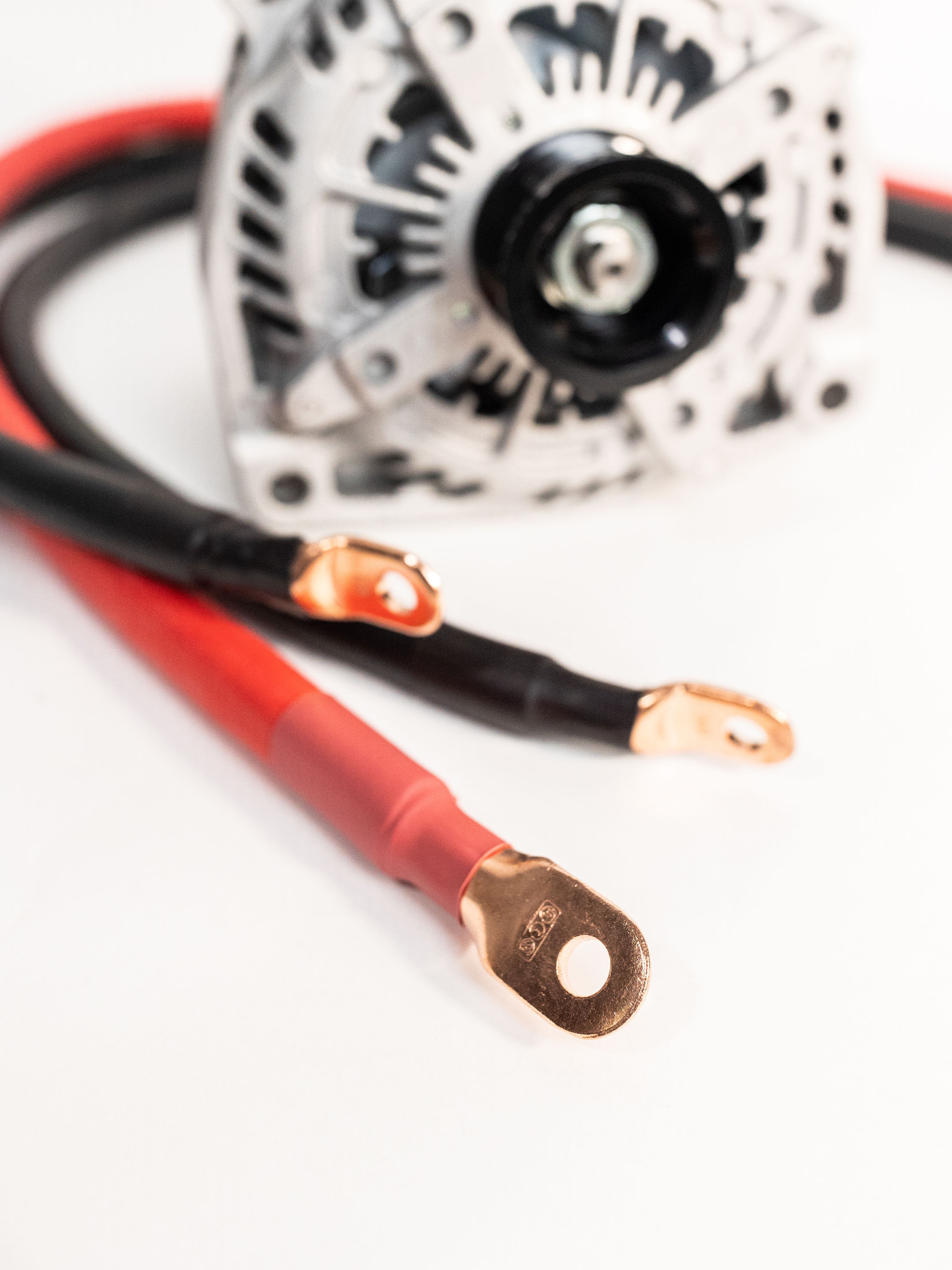

HIGH OUTPUT ALTERNATORS

POWER UP WITH THE BEST

HIGH OUTPUT ALTERNATORS

HIGH OUTPUT ALTERNATORS

Select Your Vehicle Below